HOW WE WORK

Manufacturing Process

From our sustainable rubber tree forests to your doorstep. Explore our commitment to quality at every step of the journey.

Harvest

Rubber Tree Forest & Latex Collection.

The process begins in the forest where latex sap is carefully collected from rubber trees into cups.

As it dries, it forms cup lumps, which become the raw material base for our production..

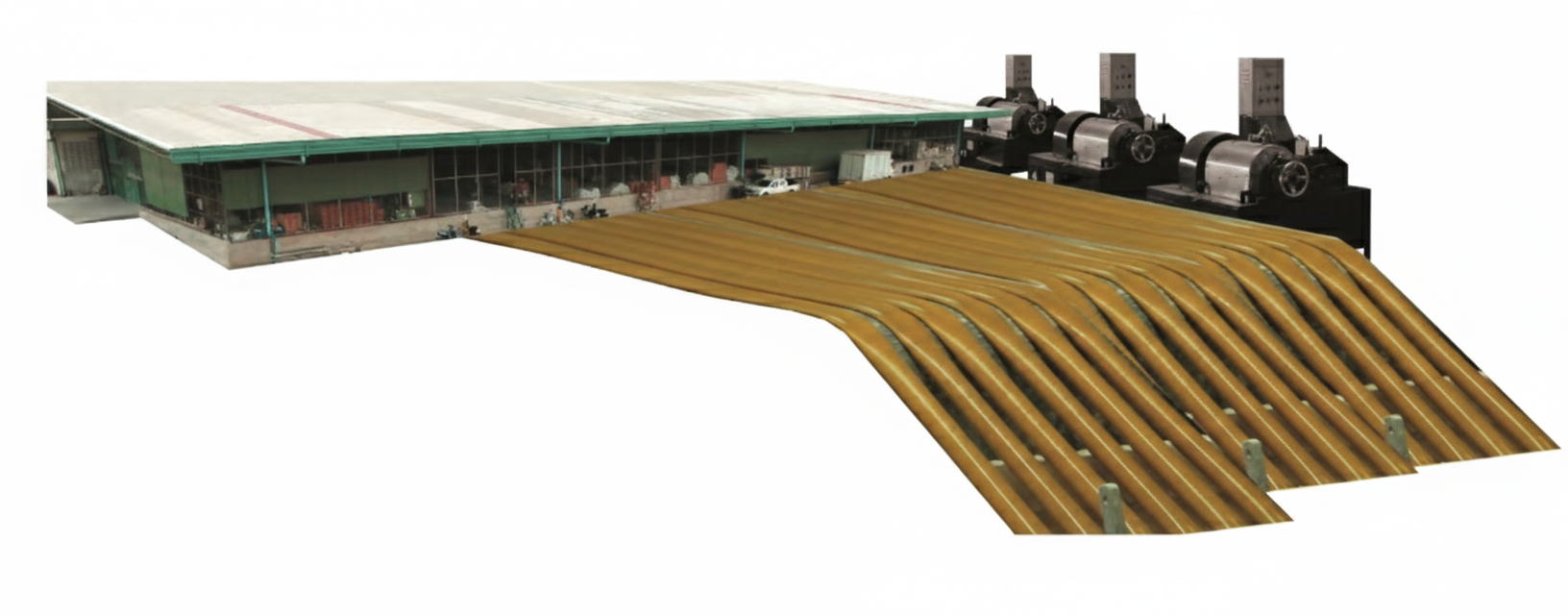

Initial Factory Process

Pressing & Smoking.

The collected rubber is mechanically pressed into sheets using a heavy-duty bale press.

These sheets are then treated in smokehouses to remove impurities and significantly enhance durability, preparing them for manufacturing..

Manufacture

Compound Preparation to Baking.

Mixing rubber with additives like CaCO3 and colorants.

Pressing and stretching the compounded master batch into sheets.

Feeding sheets through an extrusion machine to determine diameter and thickness.

Cooling extruded tubes in water, then baking to enhance tensile strength and elasticity..

Cut

Precision Slicing & Washing.

The baked rubber tubes are removed and sliced into rubber bands of the specific required width using high-speed precision cutters.

The cut bands are then washed with silicone to add a professional shine and smooth finish..

Pack & Ship

Weighing, Sealing & Logistics.

We weigh rubber bands using digital scales, heat-seal them in bags, and pack them into cartons.

The packed cartons are loaded into containers for worldwide shipping to our customers..